Firstly, the wall modules offer various possibilities for surface coating.

Secondly, it is possible to design all kinds of openings in the wall modules.

Thirdly, some modules can be replaced by other constructional and structural solutions, thus making it possible to design unique buildings.

Fourthly, without breaking up the structure, it can be decorated with architectural elements like any other building.

The remarkable simplicity and lightness of the construction is the result of many years of research, testing and development.

The contract for erecting a Baashall™ includes all works from consultations and preliminary work, erection and work on roofs to the installation of doors and windows.

The roof is equipped with thermal insulation, covered with resistant waterproof material, and a solution is provided for the drainage of rain water.

In addition, concrete buildings are more resistant to burglary and fire than any other types of buildings.

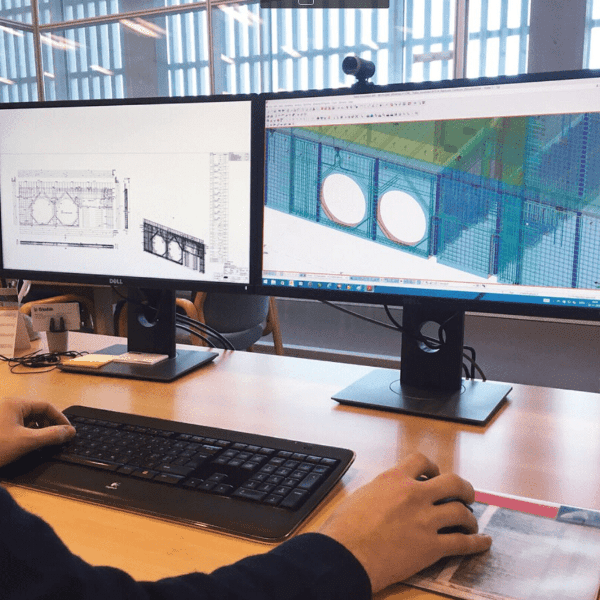

Compared to regular building constructions, a lot of time can be saved in the design phase of the basic hall due to the comprehensive preliminary work which results in standard elements and logical construction.

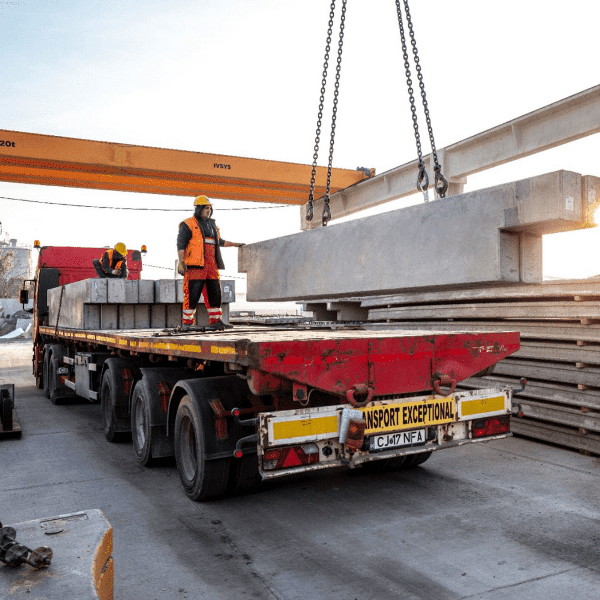

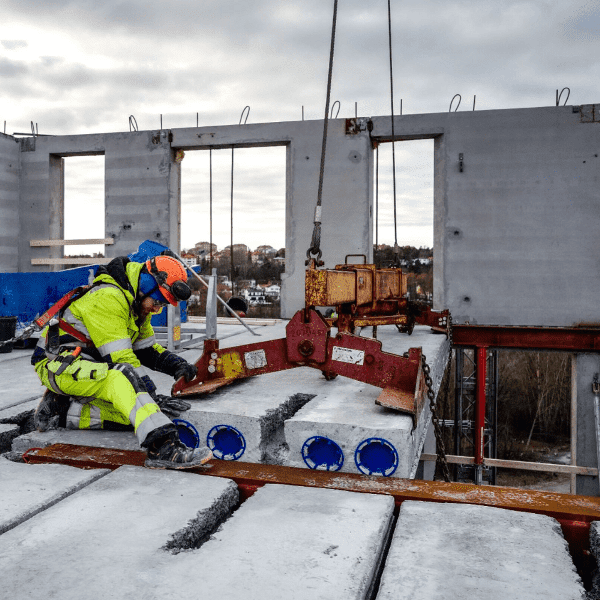

What is more, other methods of building with concrete can hardly compete with the erection speed of the basic hall at the construction site.

If necessary, the building can later be rebuilt and even taken apart and re-erected at a different site without any significant losses. The whole building is recyclable: concrete slabs that have served their purpose are crushed and turned into new concrete or aggregate.

There are no limitations to the length of a building. It is determined according to the function of your building: how many modules you decide to erect in a row.

If you need a building that is more than 24 (30) metres long, a second row of modules must simply be installed next to the first one.

In that case, the edges of roof elements rest on columns as well, but the distance between rows of columns is an incredible 24 (30) metres. Therefore, there are no limitations to the width of the building either; the only limitations to your freedom of choice are set by the dimensions of the piece of land at your disposal.

Regardless of it being standardized, modular hall can have various forms.

The vertical division of elements is characteristic of the Baashall™. An architect can either emphasize this or overshadow it by means of decorative elements.

Concrete elements are very adaptable. There is a wide choice of surface solutions, from robust natural stone grit to polished surface, from the even shade of stone to the picturesque bluish green lazure painted surface.

The Baashall™ has the ability to accumulate heat which is characteristic of concrete elements. The great thermal capacity of concrete elements creates a stable indoor climate and, since the building is well insulated, the maintenance and heating costs of the basic hall are low. This makes it possible to save on the account of air conditioners and avoid draught in the basic hall.

Room temperature is a factor affecting work efficiency that has been underrated so far. Studies have shown that when the room temperature rises above 23 degrees, work efficiency drops significantly, and when the temperature keeps rising, work efficiency declines accordingly. Lowering the room temperature has the same effect.

When the indoor climate of buildings with different structure was compared during a twenty-four hour period in summer, it became evident that the fluctuations were greatest in a metal building and slightly smaller in a concrete building, whereas the basic hall surprised everybody with its extremely stable indoor climate.

Firstly, the wall modules offer various possibilities for surface coating.

Secondly, it is possible to design all kinds of openings in the wall modules.

Thirdly, some modules can be replaced by other constructional and structural solutions, thus making it possible to design unique buildings.

Fourthly, without breaking up the structure, it can be decorated with architectural elements like any other building.

The remarkable simplicity and lightness of the construction is the result of many years of research, testing and development.

The contract for erecting a Baashall™ includes all works from consultations and preliminary work, erection and work on roofs to the installation of doors and windows.

The roof is equipped with thermal insulation, covered with resistant waterproof material, and a solution is provided for the drainage of rain water.

In addition, concrete buildings are more resistant to burglary and fire than any other types of buildings.

Compared to regular building constructions, a lot of time can be saved in the design phase of the basic hall due to the comprehensive preliminary work which results in standard elements and logical construction.

What is more, other methods of building with concrete can hardly compete with the erection speed of the basic hall at the construction site.

If necessary, the building can later be rebuilt and even taken apart and re-erected at a different site without any significant losses. The whole building is recyclable: concrete slabs that have served their purpose are crushed and turned into new concrete or aggregate.

There are no limitations to the length of a building. It is determined according to the function of your building: how many modules you decide to erect in a row.

If you need a building that is more than 24 (30) metres long, a second row of modules must simply be installed next to the first one.

In that case, the edges of roof elements rest on columns as well, but the distance between rows of columns is an incredible 24 (30) metres. Therefore, there are no limitations to the width of the building either; the only limitations to your freedom of choice are set by the dimensions of the piece of land at your disposal.

Regardless of it being standardized, modular hall can have various forms.

The vertical division of elements is characteristic of the Baashall™. An architect can either emphasize this or overshadow it by means of decorative elements.

Concrete elements are very adaptable. There is a wide choice of surface solutions, from robust natural stone grit to polished surface, from the even shade of stone to the picturesque bluish green lazure painted surface.

The Baashall™ has the ability to accumulate heat which is characteristic of concrete elements. The great thermal capacity of concrete elements creates a stable indoor climate and, since the building is well insulated, the maintenance and heating costs of the basic hall are low. This makes it possible to save on the account of air conditioners and avoid draught in the basic hall.

Room temperature is a factor affecting work efficiency that has been underrated so far. Studies have shown that when the room temperature rises above 23 degrees, work efficiency drops significantly, and when the temperature keeps rising, work efficiency declines accordingly. Lowering the room temperature has the same effect.

When the indoor climate of buildings with different structure was compared during a twenty-four hour period in summer, it became evident that the fluctuations were greatest in a metal building and slightly smaller in a concrete building, whereas the basic hall surprised everybody with its extremely stable indoor climate.